Design

Manufacture

3d Scanning

Design

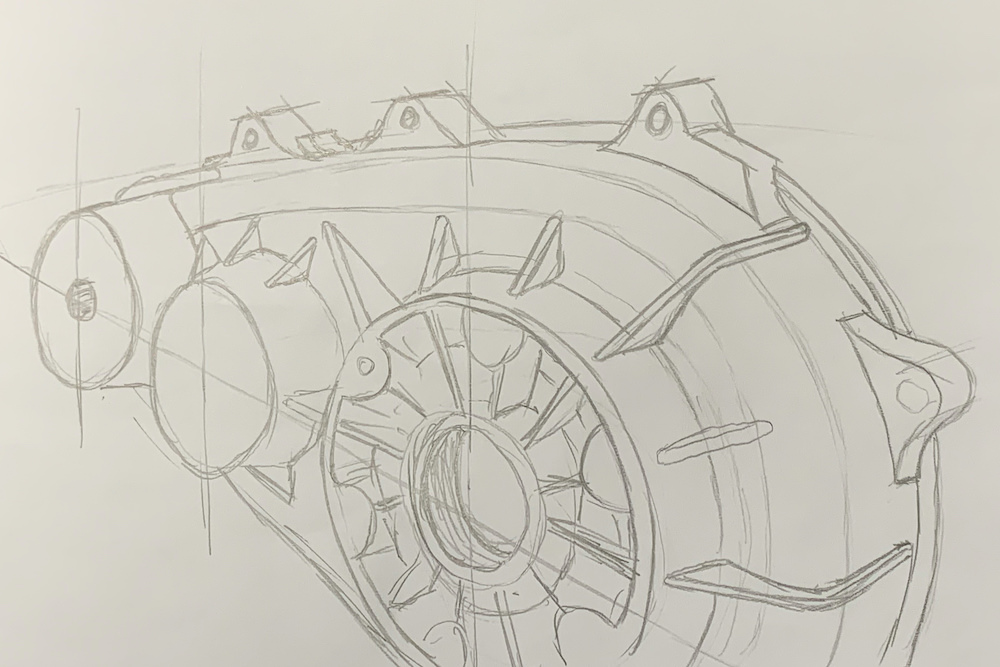

Concept

Verbal brief, simple napkin sketch, detailed drawings, or give us free rein? Whether you kinda, sorta know what you want or have an exacting and precise design brief we can work with you to design for manufacturing and realise the parts/products you need to move your project forward.

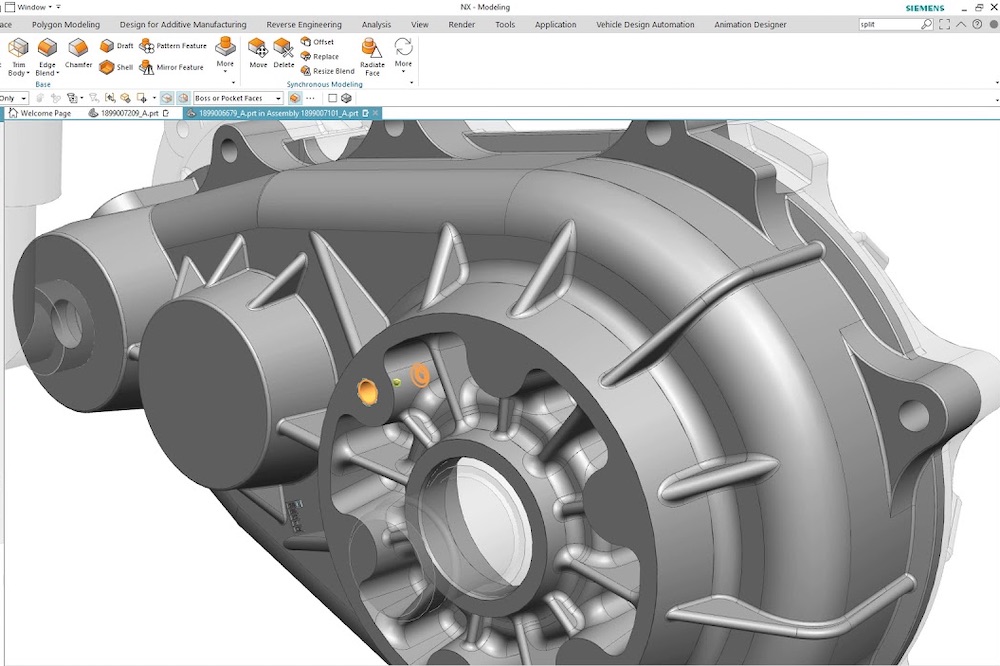

Cad

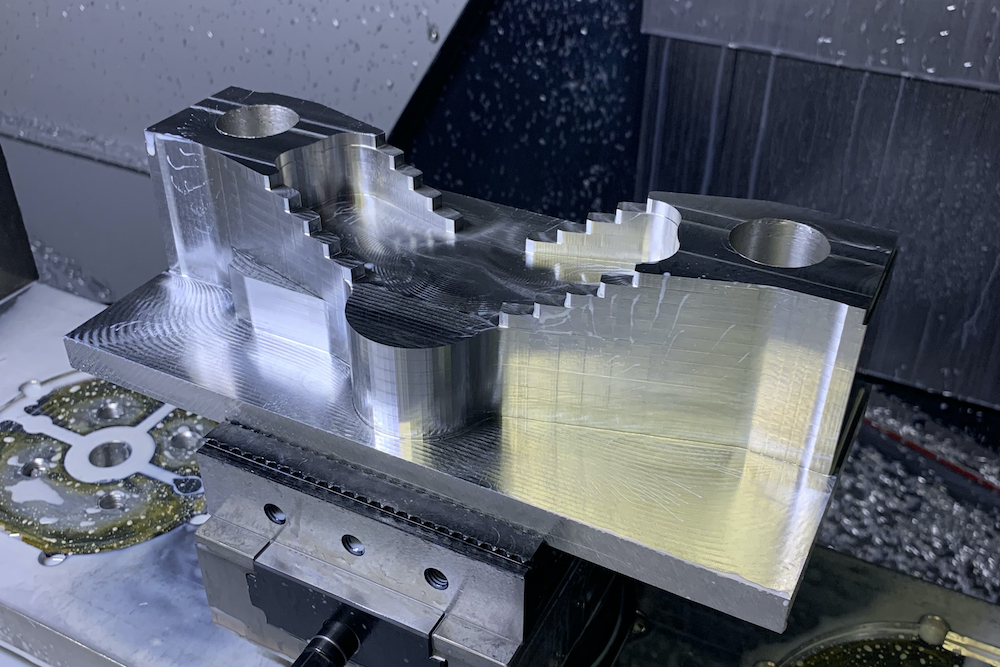

Manufacture

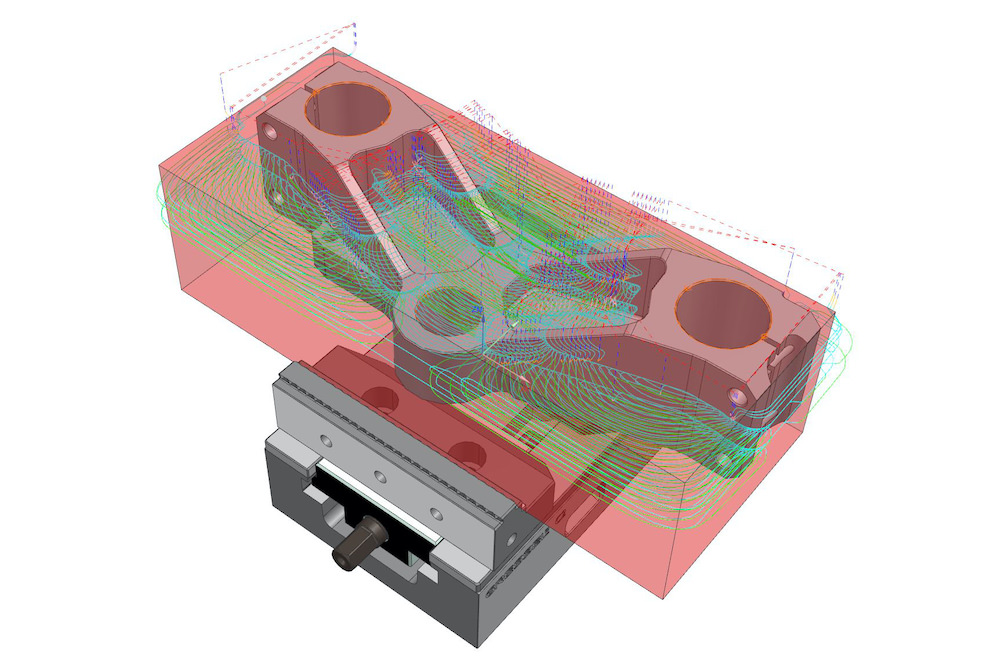

CAM

CAM - Computer aided manufacturing, the complex process of taking 3d models and making real parts. Materials, tooling, strategies, finishes and machines to be used are all parts of the equation, programming the simplest parts can be measured in minutes whilst the most complex can take days. All programmes are then verified prior to physical machining to help prevent any unforeseen surprises.

Machining

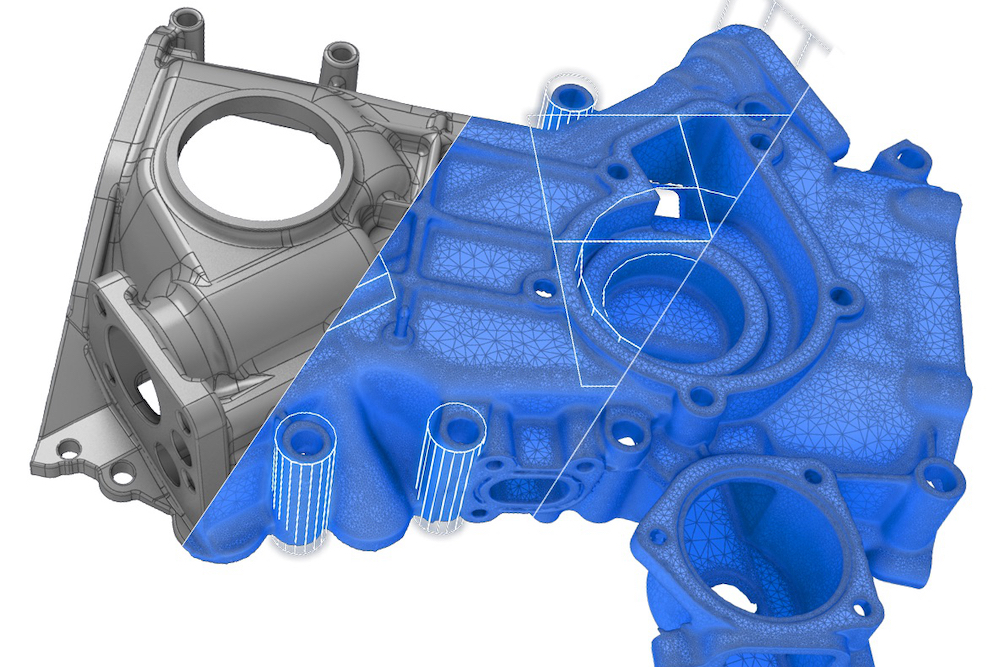

3D Scanning

Capture

Using portable hand held scanners allows us to capture scan data in a controlled environment at our premises or ‘in the field’ for those items that can’t be brought to us. From small components to whole vehicles we can capture the data needed for reverse engineering or to design new components to fit in/around existing assemblies.

Engineer

About

Concept, design, manufacture, realisation - for over forty years we have been involved in, and passionate about, all things fast and loud.

Two wheels, four wheels, on the road, in the dirt or airborne we can help you with race, street, show or restoration.

Contact

Bryce Morgan Racing

Unit 21 Anglo Trade Park

Fishponds Road

Wokingham

Berkshire

RG41 2AN

tel. +44 7525 426247

Visitors by appointment only please